Electromagnetic lockingStandard

HQMAG 2000NF3

Special range for escape doors. The HQMAG 2000NF3 is compliant with the DAS NF S61 937 and EN 13637 norms, and works at 24/48 V DC.

HQMAG 2000NF3 Manual

DownloadNotice NF: HQMAG 2000NF3

DownloadWiring and voltage setting: HQMAG 2000NF3

DownloadCertifications

DownloadLAB-TESTED HOLDING FORCE: GRADE 3+

All our electromagnets are checked in our factory at the end of the manufacturing process. Moreover, the holding force of the HQMAG 2000NF3 has been tested by independent European laboratories. The results speak for themselves and are indisputable: In the 3000N category, the HQMAG 2000NF3 is the best “grade 3+” product on the market. Don’t hesitate to ask us for test results and don’t forget to do the same with other big players on the market!

MANAGING EMERGENCY EXITS (EN 13637, CHAP. 7)

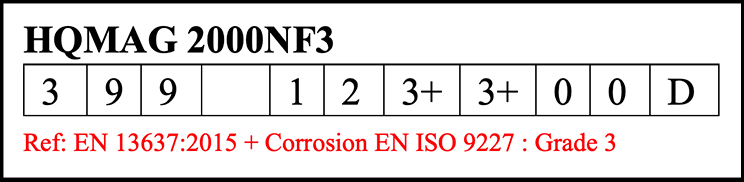

Like all our electromagnets, the HQMAG 2000NF3 complies with the requirements of EN 13637 chapter 7, the voluntary European standard on managing the systems for emergency exits. This norm requires that all the actual performances of the components of the locking parts of the system appear on a standardised label. This label is applied to all of our electromagnets.

PATENTED ELECTROMAGNETIC LOCKING

It features an exclusive MegaLED (patented innovation) which enhances security by facilitating visual or camera surveillance of access points. It indicates either the correct locking (LSS) or open access of the door via its red and green MegaLED.

ELECTROMAGNETIC LOCKING INTRINSICALLY WITHOUT MAGNETIC REMANENCE

The HQMAG electromagnets have been designed with specific, exceptionally high quality materials according to our unique know-how, and have never been defective for 35 years and counting. This dual requirement allows HQMAG to offer the only electromagnets intrinsically without remanence. Therefore, at HQMAG, no mechanical repeller, or electric repeller (Kick-off), with reliability that is uncertain over time is added. On standard electromagnets, these repellers are designed to prevent the electromagnet from “sticking” to its armature plate due to the unwanted retention of the magnetic field when access is to be released. Taking the risk of remanence (electromagnet with repeller) means accepting the possibility of catastrophic consequences in the event of an emergency evacuation. This is why electromagnets must, naturally, be without magnetic remanence!

HIGH CORROSION RESISTANCE and DURABILITY

HQMAG electromagnets benefit from certified corrosion-proof treatment and unmatched quality. They have passed the salt spray test (ISO 9227, ASTM B 117-90). Following this test, HQMAG electromagnets keep all their attributes and lose no more than 10%, on average, of their efficiency (compared to up to 70% for some of our competitors). These results prove the HQMAG products are resistant over time, unlike the infamous, planned obsolescence from which many technological products suffer.

ACCESSORIES THAT HANDLE MOST MOUNTING CONFIGURATIONS

Various accessories, designed for the installation of HQMAG electromagnets, are available both for push doors or pull doors as well as for doors made of wood, steel, aluminium, PVC, glass, and so on. Mounting the HQMAG 2000NF3, with or without its accessories, is simplified thanks to an intuitive and dynamic assembly manual. Universal mounting, can be fit on right and left hand doors.

L bracket: AMLB4

ZL bracket: AMZB4-LP

Fire door support: AMAB4

SPECIFICATIONS

Main Features ¹

| Security/Holding Force: | Grade 3+ (≲ 3 000N, 300kgf, 675lbf) Tol. 15% |

| Category of use: | Grade 3 (High frequency - Public use) |

| Durability/reliability: | Grade 9 ( > 1 000 000 cycles) |

| Corrosion resistance/humidity/IP protection: | Grade 3 (EN 1670, EN ISO 9227) |

| Ref | |

|---|---|

| Security/Holding Force: | Grade 3+ (≲ 3 000N, 300kgf, 675lbf) Tol. 15% |

| Category of use: | Grade 3 (High frequency - Public use) |

| Durability/reliability: | Grade 9 ( > 1 000 000 cycles) |

| Corrosion resistance/humidity/IP protection: | Grade 3 (EN 1670, EN ISO 9227) |

Our main HQMag products features are displayed on the products with a certified sticker responding to the EN 13637, chap 7 norm.

Technical data

| Mounting: | Surface |

| Residual magnetism: | 0% - By design (No push-pin, no electronic kick-off) |

| Locking monitoring (LSS): | Reed + MegaLed |

| Electrical/spark protection: | Built-in metal-oxyde varistor (MOV) |

| Power: | 24/48VDC - 250/125 mA - Remote: 0,1W |

| Environmental protection / IP Rating ²: | IP 43 (fixed under header) |

| Sizes (L x h x w): | 238 x 48 x 26 mm |

| Weight: | ~2 kg |

| Environmental / Temperature: | -40°C to +60°C |

| Compliances: | NF S61 937-x, CE 2014/30/EU, EN 13637 (Chap.7) 2015, EN 1670, EN ISO 9227, ASTM B 117, RoHS/Reach |

| Ref | |

|---|---|

| Mounting: | Surface |

| Residual magnetism: | 0% - By design (No push-pin, no electronic kick-off) |

| Locking monitoring (LSS): | Reed + MegaLed |

| Electrical/spark protection: | Built-in metal-oxyde varistor (MOV) |

| Power: | 24/48VDC - 250/125 mA - Remote: 0,1W |

| Environmental protection / IP Rating ²: | IP 43 (fixed under header) |

| Sizes (L x h x w): | 238 x 48 x 26 mm |

| Weight: | ~2 kg |

| Environmental / Temperature: | -40°C to +60°C |

| Compliances: | NF S61 937-x, CE 2014/30/EU, EN 13637 (Chap.7) 2015, EN 1670, EN ISO 9227, ASTM B 117, RoHS/Reach |

2 Electrical connections shall be protected according to the installation environment.