Hybrid locking - VortexVortexEscape route

VX 2400-ESCAPE

Universal solution, simple and affordable, in response to conflicts between the safety of people and the security of property, in the context of emergency exits.

Manual: VX 2400-ESCAPE

DownloadNF Manual: VX 2400-ESCAPE

DownloadCertifications

DownloadVX 2400-ESCAPE Catalogue

DownloadTHE "ALL-IN-ONE" SOLUTION THAT ENDS THE ETERNAL CONFLICT BETWEEN SECURITY AND SAFETY

The Vortex Escape (VX2400-Escape) is born from the desire to include the management of emergency exits in a new paradigm. It consists of developing a universal solution, simple and affordable, in response to conflicts between the safety of people and the security of property regarding evacuation routes.

Indeed, also called emergency exits, these doors must not only allow the premises to be evacuated, without constraints, in case of danger, but also in the majority of the cases to prevent any unauthorized exit.

This paradox of both locked and free access has so far only been managed by installing systems (known as UGIS, French acronym which stands for “emergency exits control unit”) that are as sophisticated as they are costly. Furthermore, these systems require the permanent control of a human.

As a consequence, small or medium sized sites which cannot afford such investments, finish up locking their doors with chains, padlocks or others. These systems are not ideal and, in fact, compromise all personal safety in the event of a disaster requiring rapid evacuation.

CHALLENGES TO BE MET

In developing the VORTEX ESCAPE, the challenge was to integrate, within a compact unit:

• a very efficient locking system (patented Vortex technology)

• an intelligence capable of interpreting data from its own sensors as well as external information

• a capacity of action at the door it controls.

These elements make the Vortex Escape a unique “all-in-one” solution on the market.

VORTEX, THE INTELLIGENT HYBRID LOCKING BY HQ MAG

The basis of the system is the hybrid locking system called Vortex and particularly known for its exceptional holding force of 15,000N and for its pressure sensors which trigger an alarm in the event of abnormal constraints on the door. (For further information on the locking part of the VX2400-ESCAPE see VX2400LP)

ALL-IN-ONE MANAGEMENT OF THE EMMERGENCY EXITS = VORTEX LOCKING + CAMERA SIGNALISATIONS MICRO-INTELLIGENCE

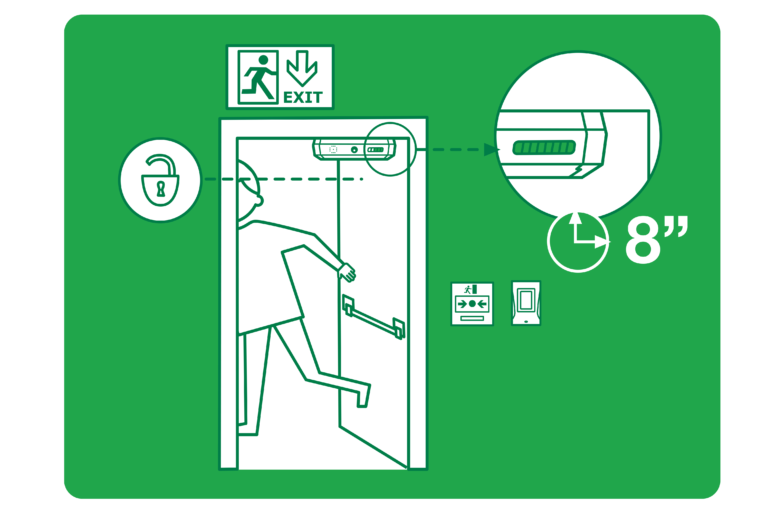

To provide real management of the emergency exit, the VX2400-Escape is equipped with numerous inputs dedicated to external information (green glass breakage, fire panel link, access control, reset, etc.) which support the incorporated sensors (camera, pressure sensor, door position sensor and of good locking,…). The set of information collected allows the on-board micro-intelligence to deduce the appropriate action to the situation.

A 8-SEGMENT MEGALED WHICH OPERATES AS A TIMEOUT INDICATOR

This high-end hybrid locking system is equipped with a MegaLed for easy long-distance visibility and supervision. This function allows you to check the locking status of the door from a distance. This Megaled also indicates the start of the countdown (t1) before opening access.

QUICK INSTALLATION ON NEW OR EXISTING DOORS

A Vortex-Escape can be installed quickly on any existing door without modifying the equipment already present (eg panic bars or similar, etc.). Only a 24VDC – 7,2W (Remote 0,35W) power supply, and a pressure initialization element (BBG / DM green “glass breaker” box), are required as external accessories. An intuitive and practical installation guide has been developed to meet the different scenarios managed by the VX2400-ESCAPE. You can download it on this page.

A NEW GLOBAL PATENT FOR A COMPREHENSIVE, RELIABLE AND INNOVATIVE SOLUTION.

The VORTEX ESCAPE is the result of more than two years of research into the development of an emergency exit management solution that fully meets the many international standards. This investment in the service of greater safety and security has enabled HQ MAG to patent the VORTEX ESCAPE worldwide. We are therefore the only ones on the market able to offer you this innovative, reliable, highly secure and financially affordable solution for “All-in-one” emergency exit management!

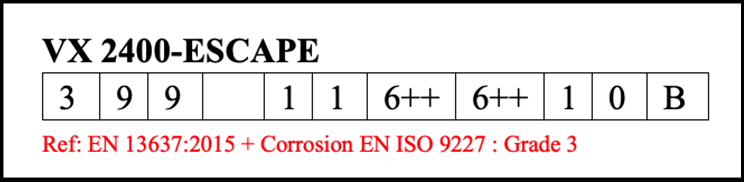

SPECIFICATIONS

Main Features¹

| Security/Holding Force: | Grade 6++ (15 000N) |

| Category of use: | Grade 3 (High frequency - Public use) |

| Durability/reliability: | Grade 9 ( > 1 000 000 cycles) |

| Corrosion resistance/humidity/IP protection: | Grade 3 (EN 1670, EN ISO 9227) |

| Security/Holding Force: | Grade 6++ (15 000N) |

| Category of use: | Grade 3 (High frequency - Public use) |

| Durability/reliability: | Grade 9 ( > 1 000 000 cycles) |

| Corrosion resistance/humidity/IP protection: | Grade 3 (EN 1670, EN ISO 9227) |

Our main HQMag products features are displayed on the products with a certified sticker responding to the EN 13637, chap 7 norm.

Technical data

| Mounting: | Surface |

| Residual magnetism: | 0% - By design (No push-pin, no electronic kick-off) |

| Locking monitoring (LSS): | Built-in reed contact |

| Door position monitoring (DSS): | Built-in reed contact |

| Early break-open warning alarm (EW): | Built-in pull dynamic sensor + micro-relay + built-in buzzer |

| Electrical/spark protection: | Built-in metal-oxyde varistor (MOV) |

| Power: | 24VDC - 7,2W / 0,35W |

| Environmental protection / IP Rating ²: | IP 43 (fixed under transom) |

| Sizes (L x h x w): | 223 x 39,4 x 64 |

| Weight: | ~1,7 kg |

| Environmental / Temperature: | From -20°C to +60°C |

| Compliances: | NF S61 937-x, CE 2014/30/EU, EN 13637 (Chap.7) 2015, EN 1670, EN ISO 9227, ASTM B 117, RoHS/Reach |

| Mounting: | Surface |

| Residual magnetism: | 0% - By design (No push-pin, no electronic kick-off) |

| Locking monitoring (LSS): | Built-in reed contact |

| Door position monitoring (DSS): | Built-in reed contact |

| Early break-open warning alarm (EW): | Built-in pull dynamic sensor + micro-relay + built-in buzzer |

| Electrical/spark protection: | Built-in metal-oxyde varistor (MOV) |

| Power: | 24VDC - 7,2W / 0,35W |

| Environmental protection / IP Rating ²: | IP 43 (fixed under transom) |

| Sizes (L x h x w): | 223 x 39,4 x 64 |

| Weight: | ~1,7 kg |

| Environmental / Temperature: | From -20°C to +60°C |

| Compliances: | NF S61 937-x, CE 2014/30/EU, EN 13637 (Chap.7) 2015, EN 1670, EN ISO 9227, ASTM B 117, RoHS/Reach |

2 Electrical connections shall be protected according to the installation environment.